Alumina Refractory Castable

Product Information

| Product Name | Refractory Castable |

| Genera | Humilis Caementum Castable / Altitudo Fortitudo Castable /Altum Alumina Castable / PERFUSORIUS Castable |

| Compositio | Aggregata refractaria, pulverulenta et dolabra |

| Features | 1. Securus Construction; 2.Good Slag Resistentia, 3.Good Corrosio Resistentia 4.Good Ignis Resistentia, 5.Energy Salutis Ac Environmental Praesidium. |

| Applications | Late usus est in Fornacibus variis High Temperature Industrial. |

| Products | Humilis Caementum Castable | Princeps Fortitudo Castable |

| Descriptio | Castabuli caementum humile ad novos castellas cum minimo ligatorio caemento referuntur.Copia castellarum refractoriae societatis maximum est fere 15% ad 20%, et caementum castellorum humilium circiter 5% est, et quaedam etiam ad 1% ad 2% redacta sunt. | Altae roboris indumentum castable repugnans componitur ex aggregato virium altorum, mixturae mineralis, aggregatae virium altae et anti rima et agente resistente. |

| Features | Impetu scelerisque resistentia, resistentia scoria, resistentia exesa signanter emendantur, similes laterum refractoriarum superantes. | Maximum robur, princeps lapsum resistentia, impulsum resistentia, exesa resistentia, anti-oleum permeabilitas, figura arbitraria moderatio, fortis integritas, simplex constructio, bonae constructionis effectus, et longus usus. |

| Applications | 1. Lining variarum caloris fornacibus curationum, fornacibus calefacientibus, fornacibus scapo, fornacibus gyratoriis, opercula fornacis electrica, tapholes fornaces inspirationis; 2. Castables se-fluentes humiles caementa sunt apta ad imbrem calidissimum liniamenta tormentorum ad rores metallurgias et petrochemical catalyticas rimas reactorias linire repugnantes, tunica exterioris fornacis calefaciendi fistulam refrigeratam, etc. | Linas vestium renitens stratum slagae screae;aes canalis, calculus, hopper et silo in metallurgia, calculus, potentia scelerisque, chemica;cemento et aliis industriis et flatu fornace permixtis silo, sintering silo, satietas, pelletizer, etc. |

| Products | Alumina Castable | Leve Castable |

| Descriptio | Altus alumina castables sunt refractoriaecastables e altus alumina rudisut aggregata et pulverulenta et additaligatis. | Leve pondus castabile cum densitate vili facta est caementa aluminata, alta alumina, materia tenuis, ceramsita, et additiva. |

| Features | Magna vis mechanica et bonum scelerisque concussa resistentia, abrasio resistentia et aliae proprietates. | Minimum mole densitatis, parva scelerisque conductivity, bonum scelerisque velit effectus, alta vis compressiva, acidum et acidum gas corrosio resistentia, calor velit, scelerisque velit, et humilis aqua effusio. |

| Applications | Maxime utendum est ut interior tunica boilers, fornax furoris, fornacis calefactionis, fornacibus calefacientibus, fornacibus ceramicis et aliis fornacibus. | Leve pondus castabile adhiberi potest ad thermas Nullas iacuit summus temperatus fornax industrialis et armorum etiam usus est ad tunicam organorum gasorum summus temperatus variarum. |

Product Index

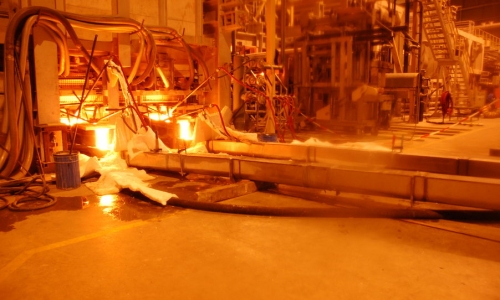

Hot Blast Stove

Cuniculum Kiln

Gyratorius Kiln

Industria ferri et chalybe: maxime adhibita ad sustentationem et inaequationem fornacibus arcus electrici, fornacibus chalybeis, capulis aliisque instrumentis adhibitis.

Industria metalli non ferrea: adhibita ad deprimendam et reparandam cupri, aluminii, zinci, nickel et aliorum metalli non-ferrosi fornacibus excoquentibus et convertentibus.

Industria vitrea: usus ad sustentationem et commissuram fornaces vitreas, furnum furnum et alia instrumenta.

| Product Name | Humilis Caementum Castable | |||||

| INDEX | RBTZJ-42 | RBTZJ-60 | RBTZJ-65 | RBTZJS-65 | RBTZJ-70 | |

| Opus Low Temperature | 1300 | 1350 | 1400 | 1400 | 1450 | |

| Mole densitas (g/cm3)110℃×24h ≥ | 2.15 | 2.3 | 2.4 | 2.4 | 2.45 | |

| Frigus tendentes virtus110℃×24h(MPa) ≥ | 4 | 5 | 6 | 6 | 7 | |

| Frigus comminuens fortitudo (MPa) ≥ | 110℃×24h | 25 | 30 | 35 | 35 | 40 |

| CT℃×3h | 50 1300℃×3h | 55 1350℃×3h | 60 1400℃×3h | 40 1400℃×3h | 70 1400℃×3h | |

| Permanens Linearibus Mutationem@CT℃×3h(%) | -0.5~+0.5 1300℃ | -0.5~+0.5 1350℃ | 0~+0.8 1400℃ | 0~+0.8 1400℃ | 0~+1.0 1400℃ | |

| Concursores scelerisque Resistentia (1000℃ aquam) ≥ | . | . | . | 20 | . | |

| Al2O3(%) ≥ | 42 | 60 | 65 | 65 | 70 | |

| CaO(%) ≤ | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| Fe2O3(%) ≤ | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Product Name | Princeps Fortitudo Castable | |||||

| INDEX | HS-50 | HS-60 | HS-LXX | HS-80 | HS-90 | |

| Opus temperatus modus (℃) | 1400 | 1500 | 1600 | 1700 | 1800 | |

| 110℃ mole densitatis(g/cm3) ≥ | 2.15 | 2.30 | 2.40 | 2.50 | 2.90 | |

| Modulus Rupture(MPa) ≥ | 110℃×24h | 6 | 8 | 8 | 8.5 | 10 |

| 1100℃×3h | 8 | 8.5 | 8.5 | 9 | 9.5 | |

| 1400℃×3h | 8.5 1300℃×3h | 9 | 9.5 | 10 | 15 | |

| Frigus comminuens fortitudo (MPa) ≥ | 110℃×24h | 35 | 40 | 40 | 45 | 60 |

| 1100℃×3h | 40 | 50 | 45 | 50 | 70 | |

| 1400℃×3h | 45 1300℃×3h | 55 | 50 | 55 | 100 | |

| Permanens Linearibus (%) | 1100℃×3h | -0.2 | -0.2 | -0.25 | -0.15 | -0.1 |

| 1400℃×3h | -0.45 1300℃×3h | -0.4 | -0.3 | -0.3 | -0.1 | |

| Al2O3(%) ≥ | 48 | 48 | 55 | 65 | 75 | 90 |

| CaO(%) ≤ | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Fe2O3(%) ≤ | 3.5 | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 |

| Product Name | Alumina Castable | ||||||

| INDEX | Al2O3(%) ≥ | CaO(%) ≥ | Refractio (℃) | CT℃×3h PLC ≤1% | 110℃Post exsiccans (MPa) | ||

| CCS | MOR | ||||||

| Lutum Bonded | NL-45 | 45 | . | 1700 | 1350 | 8 | 1 |

| NL-60 | 60 | . | 1720 | 1400 | 9 | 1.5 | |

| NL-70 | 70 | . | 1760 | 1450 | 10 | 2 | |

| Caementum Bonded | GL-42 | 42 | . | 1640 | 1350 | 25 | 3.5 |

| GL-50 | 50 | . | 1660 | 1400 | 30 | 4 | |

| GL-60 | 60 | . | 1700 | 1400 | 30 | 4 | |

| GL-70 | 70 | . | 1720 | 1450 | 35 | 5 | |

| GL-85 | 85 | . | 1780 | 1500 | 35 | 5 | |

| Humilis Caementum Bonded | DL-60 | 60 | 2.5 | 1740 | 1500 | 30 | 5 |

| DL-80 | 80 | 2.5 | 1780 | 1500 | 40 | 6 | |

| Phosphate Bonded | LL-45 | 45 | . | 1700 | 1350 | 20 | 3.5 |

| LL-60 | 60 | . | 1740 | 1450 | 25 | 4 | |

| LL-75 | 75 | . | 1780 | 1500 | 30 | 5 | |

| Sodium Silicate Bonded | BL-40 | 40 | . | . | 1000 | 20 | . |

| Product Name | Leve Castable | ||||||

| Opus modus temperatus | 1100 | 1200 | 1400 | 1500 | 1600 | ||

| 110℃ mole densitatis(g/cm3) ≥ | 1.15 | 1.25 | 1.35 | 1.40 | 1.50 | ||

| Modulus Rupture(MPa) ≥ | 110℃×24h | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100℃×3h | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400℃×3h | . | . | 3 | 10.8 | 8.1 | ||

| Frigus comminuens virtus (MPa) ≥ | 110℃×24h | 8 | 8 | 11 | 12 | 10 | |

| 1100℃×3h | 4 | 4 | 5 | 11 | 10 | ||

| 1400℃×3h | . | . | 15 | 22 | 14 | ||

| Permanens Linearibus (%) | 1100℃×3h | -0.65 1000℃×3h | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400℃×3h | . | . | -0.8 | -0.55 | -0.45 | ||

| Scelerisque conductivity(W/mk) | 350℃ | 0.18 | 0.20 | 0.30 | 0.48 | 0.52 | |

| 700℃ | 0.25 | 0.25 | 0.45 | 0.61 | 0.64 | ||

| Al2O3(%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| Fe2O3(%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

Applicationem

Sarcina & CELLA